What is Plywood? In the current industrial plywood, in addition to MDF, MFC, Plywood plywood is also one of the preferred materials used in the production of furniture. Let’s find out the properties and applications of this wood in the article right below.

What is plywood?

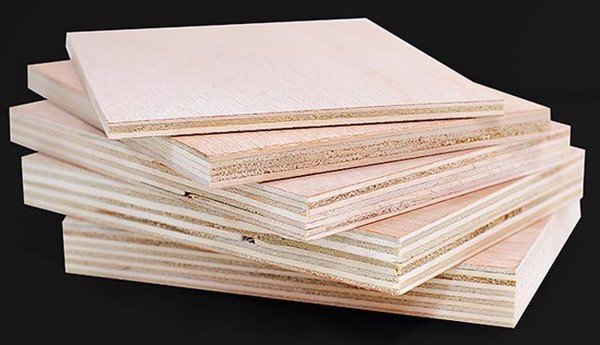

Plywood or plywood is both a different term for a type of wood made from many thin, similar-sized wood panels that are stacked and bonded with a special special glue. Plywood is used very commonly in life, especially in the design and production of furniture. Plywood wood has an advanced production process, which is pressed under high pressure and heat, so it is very good quality and ensures safe use.

History of formation and development of plywood

Learn what Plywood is. Don’t ignore the history of the first industrial wood – plywood. According to scientists, plywood has been found in tombs in Egypt claimed to have been used about 3500 years ago. In Asia, the Chinese have also known to glue thin wood panels for use since about 1000 years ago, and then European countries also began to recognize the use of this plywood.

Around the sixteenth century, the British demonstrated that gluing together thin sheets of natural wood resulted in amazingly durable wood products. It was the turning point for plywood to be “recognized” as an official industrial material and widely used around the world to this day.

Structure of Plywood

Plywood is made by joining many thin layers of wood about ~1mm thick and of equal size. These layers of wood are overlapped perpendicularly with a special glue and high temperature pressed to achieve the desired durability.

There are two types of specialized glue that are frequently used to create plywood: Phenol glue, which enhances the hardness, water resistance as well as creates a perfect plane for the wood. Meanwhile, Formaldehyde glue is resistant to warping or shrinking of wood, all cases of deformation of wood products. However, the use of this glue has limitations because it is toxic to health as well as to the environment.

Features of Plywood

One of the characteristics that every Plywood learner must know is that the number of boards used for plywood must be odd, depending on the thickness of the wood plank, using 3, 5, 7 or 9 layers. wood to form. The reason for this is to create a core layer in the middle of the wood.

Then, the two layers of wood outside the core layer will have the same grain direction. The grain direction of the outer layers will be arranged perpendicularly to increase the bearing capacity as well as prevent warping and cracking of the wood.

Plywood production process

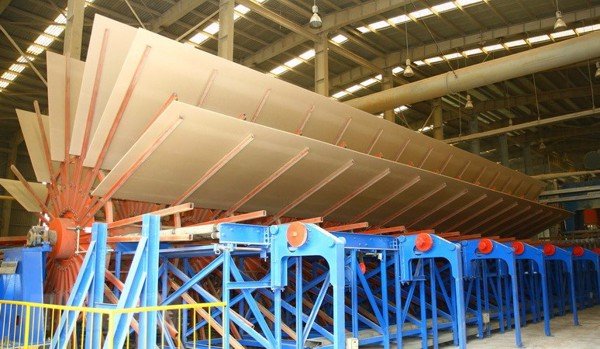

Learn the production process of Plywood plywood to help you understand the characteristics of this industrial wood. Plywood is usually produced in large-scale production facilities with a closed process as well as using many modern technology machines. Let’s go through the basic steps to make a quality plywood board right below.

Step 1: Specialized equipment will cut logs from natural wood according to the prescribed dimensions to ensure the smoothness and uniformity of the wood. These logs are then peeled off into thin layers to prepare for the gluing process.

Step 2: Normally, the layers of wood will be cut with a size of 8 x 2 feed, the core layer is only about 4 x 2 feed, then a specialized industrial machine will be used to test the elasticity of the wood.

Step 3: The wood is dried with modern drying technology. The types of wood used usually hold the ideal humidity around 7% or can range from 6 to 8% is perfect.

Step 4: At this step, the wood layers begin to be glued and pressed by machine to initially create the desired wood plywood panels. However, this stage has not finished the wood glue process.

Step 5: This is the most important step that determines the quality of the plywood panels. Pre-pressed wood will be put into the line for temperature pressing with standard pressure to ensure absolute adhesion and certainty.

Step 6: The wood after being pressed is cut into rectangular panels, treated to create a smooth and uniform surface.

Step 7: Continue to spray glue and glue the surface, the wood is pre-pressed, heat pressed with pressure for 4 more times before moving to the final cutting stage to form the plywood panels that we often use in competition. furniture work.

The sophisticated and rigorous production process of Plywood plywood makes many people believe that this wood will gradually replace natural wood to become a frequently used material in interior design with many outstanding advantages. on that you are about to learn about right below.

Advantages and disadvantages of plywood plywood

Learn what Plywood is, do not ignore the advantages and disadvantages of plywood to really consider whether this wood is suitable for use in home interiors and if so, what kind of furniture should be used. from plywood is the most reasonable.

Advantages of Plywood

High hardness and durability

Experiencing the glue spraying and heat pressing process many times, plywood is said by experts to possess relatively high hardness and durability. Especially with modern production technologies, Plywood wood is tested and evaluated for its durability and elasticity through every step, each production stage is very meticulous.

More water resistant than MDF

MDF is one of the industrial wood products with good moisture resistance, but Plywood is slightly better in terms of resistance to water penetration. Especially when dropped into the water, plywood is not as prone to swelling as MDF.

What this means for home furniture: If for furniture products from MDF, you are always advised by experts that you should avoid letting the wood come into contact with water or in other environments. Low humidity can easily reduce the life of the wood, so for plywood you do not need to worry about this problem.

Faster sanding and PU coating time

Durable Plywood wood surface is quite smooth, especially the wood that goes through the production stages to help own a smooth surface that is easy to perform decorative steps such as sanding or applying Pu paint on top.

In addition, wood also has good screw and adhesion ability, and at the same time, the price of plywood is much more reasonable than that of rare and precious natural woods, as well as the elegant beauty that easily matches the needs of the environment. Modern interior space should be very popular nowadays, especially for young families.

Disadvantages of Plywood

Cheap price but higher than MDF, MFC

It is understandable that Plywood plywood has a higher price than MDF or MFC because of its high water resistance and moisture resistance as well as smooth surface. However, the difference between industrial woods is not much, you can completely choose for yourself materials that are suitable for your family’s economic conditions as well as the purpose and environment of using each type of wood.

Plywood edge is prone to chipping

A disadvantage shared by many people who have used plywood is that the edge of plywood is very easy to chip during cutting or during long-term use. One of the important things when using plywood that homeowners need to pay attention to is to always wrap the edges of the plywood, if in the process of using these layers, scratches reveal the wood edges, it is very easy to chip. chipped, unsightly.

Easy to warp, separate layers

This is very easy to happen to non-standard plywood production facilities, “eating less” of the stage, pressing wood not according to specifications and standards or using the wrong type of specialized glue. There are many errors in the manufacturing process that cause plywood to warp, rough surface when exposed to high temperature or delamination when in high humidity environment.

To limit this phenomenon, homeowners need to find the right manufacturer and supplier of quality plywood products, with a clear and transparent production process. Because plywood if done fully according to the process will have high durability and rarely encounter the above cases.

The color is not beautiful with MDF, MFC

As many people who have used Plywood plywood, all agree that this wood has uneven colors and textures like MDF or MFC. Because of this, plywood is not used much in common spaces such as living rooms, kitchens, but often used in bedrooms, offices, floors, decorative shelves … products that have wooden surfaces. no need to be perfect.